The Shanghai-Chongqing-Chengdu high-speed railway is a high-speed railway connecting Shanghai, Chongqing and Chengdu in China.

It is the main line part of the “Riverside Corridor” in the “eight vertical and eight horizontal” high-speed railway passenger passages in the “Medium and Long-Term Railway Network Planning”. The total length of the line is 313.8 kilometers, of which the new line is 295.9 kilometers long.

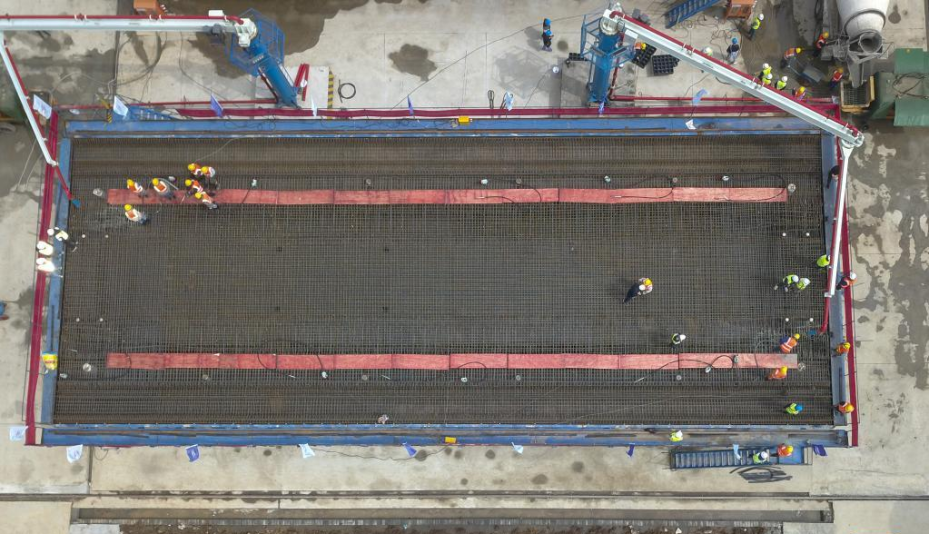

Relying on years of technical accumulation in the field of steel bar processing machinery, our company has concentrated on research and meticulously tackled the differentiated demand for steel bar products in each link of high-speed rail box girder prefabrication construction. According to the project requirements of China Railway 11th Bureau Group Bridge Co., Ltd., we helped to build the first Shanghai-Chongqing-Chengdu project Wuyi section WYZQ-5 standard Jingmen Zhongxiang beam yard.

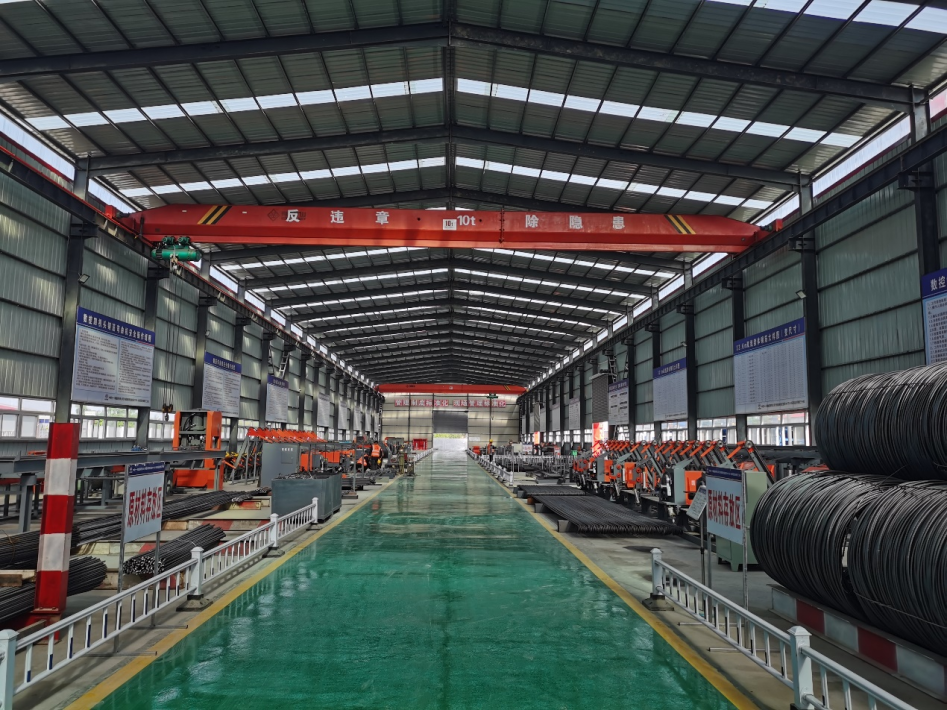

Among them, steel bar processing digital projects include GQX-300 CNC steel bar shearing production line, GWXL2-32D CNC bending center, GWXL4-25D CNC bending center, GQX-GWX-25 CNC steel bar shearing and bending integrated production line, GGJ12 CNC steel bar bending hoop machine, GT5-12 straightening machine (32 meters), GTWQ12 straightening five heads, HJDW12 welding positioning net and other equipment. A variety of steel bar products can be customized to produce high-speed rail box girder prefabricated construction.

In addition, CABR/M joined hands with China Railway Research Institute Group Co., Ltd. to develop steel bar processing management software system and steel bar processing remote control system to create an intelligent control center.

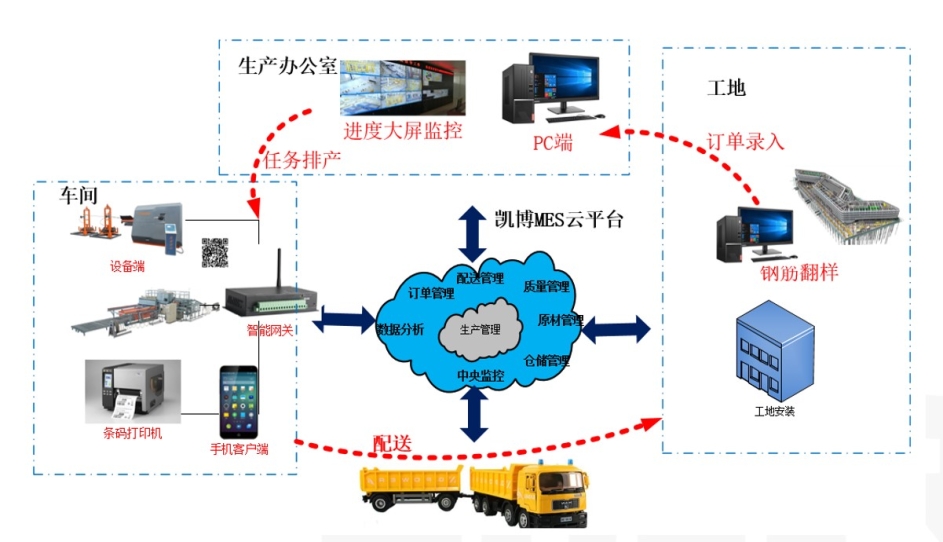

The steel bar processing management software system takes the material flow management in the steel bar processing process as the core, and realizes multi-project and multi-task remote order management with the help of industrial Internet, cloud services, intelligent equipment and other technical means, and realizes order scheduling, production order distribution, and production sign printing. , Finished products report for work, finished products in and out of the warehouse and other functions.

At the same time, it can realize the dynamic real-time monitoring of project orders and the centralized display of the overall operation status of the processing plant on the large electronic screen.

The steel bar processing remote control system can display the production status of various equipment in the processing field in real time, and at the same time realize the remote control of the start and stop of the field equipment by the central control room, creating a new digital mode of steel bar processing in the high-speed rail beam field!

The successful production of Jingmen Zhongxiang beam factory shows that the digital steel bar processing center built by CABR/M can effectively improve the productivity and ensure the quality of the project.

In order to realize the automation and intelligence of the whole process of steel bar processing for various specifications of high-speed rail box girder in road and bridge projects, CABR/M has made its own unique contribution.