Parallel Thread Rebar Splicing with Rolled End

1. Cutting off the end of rebar; 2. Stripping the ribs at the end of rebar and t…

Working Capacity 16-40mm

Function Rebar Upsetting, Thread Cutting.

Rebar Grade HRB400 and HRB500

Standard JGJ107, UBC1997, BS8110, NF35-20-1, DIN1045, ISO15835

CABR rebar parallel thread splicing with upsetting thread end designed for the connection of concrete reinforcing bars from Φ12 –Φ40. We could produce coupler as your technical requirements. We also could provide complete rebar splicing solutions for your construction project’s demands.

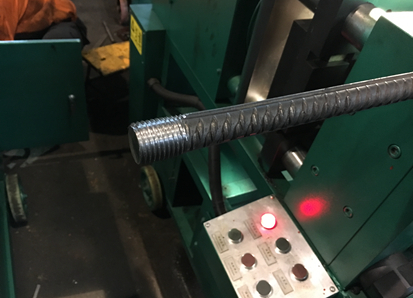

1) Cutting off the end of rebar;

2) Enlarging the end of rebars by upsetting;

3) Making parallel threads;

4) Splicing rebars by coupler.

|

Model |

LD1200 |

LD1800 |

DC2500 |

|

Working Capacity (mm) |

16-32 |

16-40 |

16-40 |

|

Rated Forging Oil Pressure (Mpa) |

35 |

35 |

35 |

|

Rated Upset Force (KN) |

1200 |

1800 |

2500 |

|

Dimensions (mm) |

660*360*360 |

810*410*410 |

1380*670*1240 |

|

Weight (kg) |

380 |

625 |

1200 |

|

Model |

BSB6 |

DBS10/35 |

|

Rated Oil Pressure (Mpa) |

40 |

30 |

|

Rated Flow (L/MIN) |

6.0 |

10-35 |

|

Power of Motor |

4.0 |

7.5 |

|

Dimensions (mm) |

460*460*640 |

1650*1000*1070 |

|

Weight (kg) |

89 |

300 |

|

Model |

QTL-40 |

|

Power of Main Motor (kw) |

4.0 |

|

Reductor Ratio |

1: 35 |

|

Dimensions (mm) |

1170*710*1140 |

|

Weight (kg) |

484 |

|

Rebar Dia.(mm) |

Outside Dia.(mm) |

Coupler Length(mm) |

Screw Thread Size(mm) |

Weight (kg) |

|

D12 |

20 |

28 |

M14*2.0 |

0.048 |

|

D 14 |

23 |

28 |

M16*2.0 |

0.06 |

|

D 16 |

26 |

32 |

M18*2.0 |

0.09 |

|

D 18 |

30 |

36 |

M22*2.5 |

0.11 |

|

D 20 |

33 |

40 |

M24*2.5 |

0.15 |

|

D 22 |

35 |

44 |

M25*2.5 |

0.18 |

|

D 25 |

40 |

50 |

M29*3.0 |

0.27 |

|

D 28 |

46 |

56 |

M32*3.0 |

0.42 |

|

D 32 |

50 |

64 |

M36*3.0 |

0.53 |

|

D 36 |

58 |

72 |

M40.3*3.5 |

0.90 |

|

D 40 |

64 |

80 |

M45.3*3.5 |

1.08 |

|

Rebar Grade |

Yield strength: 500Mpa, Tensile strength: 630Mpa -In China its model: HRB500 |

|||

|

Material |

45# High quality carbon steel or according to customers’ requirements |

|||

1) High splice strength, which could exert ultimate tensile and compression strength of rebar, it could satisfy the requirements stipulated in the Chinese standard JGJ107, American standard UBC1997, British standard BS8110, French Standard NF35-20-1, German standard DIN1045, ISO15835 and other requirements in the relevant standards;

2) Easy to operate and maintain, no need for technicians, fast splicing on construction site;

3) Several types of splices, which could be suitable for rebar splicing when the rebar cage or the bending rebar is used;

4) High production efficiency, it only takes less than 1 minute to upset and make one thread on the site;

5) High adaptability, the splicing could be conducted when the power is off, or under water, or at super high position, or windy, rainy and snowy weather.

6) Environment-friendly, material-effective.

7) Inexpensive to purchase, maintain and repair.

8) The Splicing could be produced in advance without influencing the construction period.

9) Full-Tension splice, bar break under tensile tests.

10) Manufactured under strict quality assurance plan ISO 9001.